Logistics trends 2025

The 10 Biggest Logistics Trends of 2025: What defines the future of the Supply Chain?

The logistics sector never stands still. Technological innovations, societal shifts, and increasing globalization require companies to continuously adapt to change. By 2025, the pace of these changes is expected to accelerate even further. Innovations like hyperautomation and self-learning systems open up new possibilities, while sustainability and workforce management become more prominent priorities.

Quick navigation

- 1. Hyperautomation in Warehouses

- 2. Self-Learning Transport Management Systems (TMS)

- 3. Circular Logistics Models

- 4. Real-Time Visibility 2.0

- 5. Localization: The New Norm in Supply Chains

- 6. Human-Centric Logistics: Employees in the Spotlight

- 7. Sustainability as Standard

- 8. Big Data as a Competitive Weapon

- 9. Supply Chain Resilience: Flexibility First

- 10. Blockchain Collaboration in Supply Chains

Logistics Trends 2025

In this blog, we discuss the 10 key trends set to dominate the logistics sector in 2025.

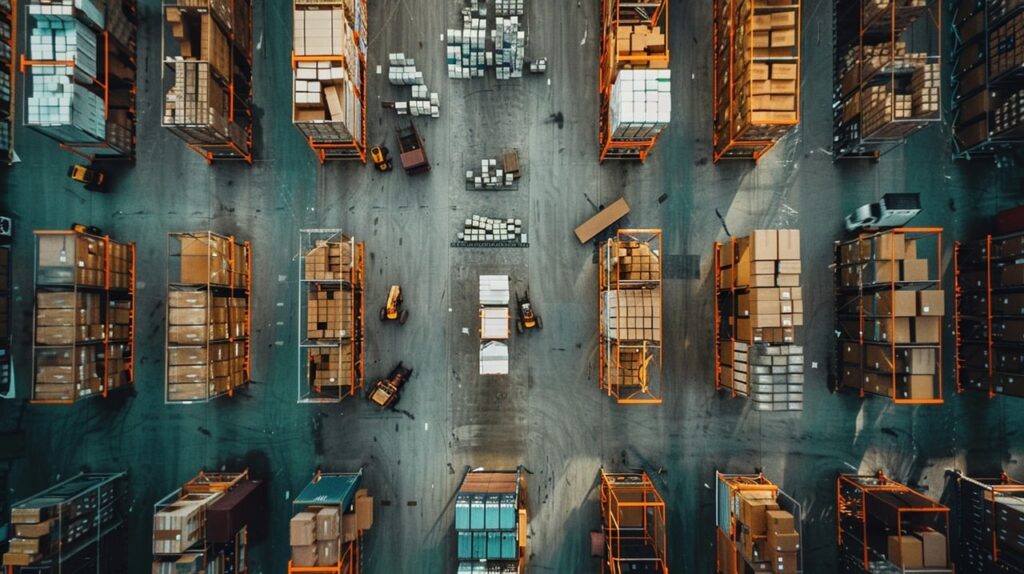

1. Hyperautomation in Warehouses

Warehouses are becoming smarter and more advanced than ever. Hyperautomation combines technologies like artificial intelligence (AI), robotics, and the Internet of Things (IoT) to fully optimize warehouse processes. This trend goes beyond simple mechanization: robots and autonomous vehicles not only perform tasks but also analyze data and make decisions. By 2025, hyperautomation will no longer be a luxury but a baseline requirement for warehouses aiming to remain competitive. This makes warehouses faster, more efficient, and more resilient in an ever-changing market.

Example:

Imagine a warehouse robot that not only picks up packages but also learns the most efficient routes and automatically finds alternatives when faced with obstacles. Hyperautomation leverages AI and machine learning to continuously improve processes.

Voordelen:

Faster and more precise order processing.

Reduced human errors.

Lower long-term operational costs.

2. Self-Learning Transport Management Systems (TMS)

Transport Management Systems (TMS) are a crucial link in modern supply chains. By 2025, these systems will leverage self-learning algorithms to continuously adapt and improve in response to changing conditions. Using AI and big data, these systems will automatically optimize routes, predict demand, and minimize fuel consumption. This not only saves costs but also helps companies achieve environmental goals. Real-time data integration enables immediate responses to unexpected events, making transport chains more flexible.

How it works:

A self-learning TMS collects data from various sources, such as traffic information, weather conditions, and freight capacity. It analyzes this data to plan the most efficient routes.

Impact on the sector:

Real-time adjustments lead to time and cost savings.

Environmental gains through reduced fuel consumption.

Improved customer service with accurate delivery forecasts.

3. Circular Logistics Models

The shift to a circular economy is also transforming the logistics sector. Circular logistics models focus on minimizing waste and maximizing reuse. This includes reverse logistics, refurbishing, and recycling products and packaging. By 2025, this approach will not only be driven by regulations but also by consumers demanding sustainability. Companies investing in circular processes will benefit from an improved environmental image, reduced raw material costs, and new revenue models.

Practical examples:

Companies like Dell and Philips give products a second life through refurbishing. This involves repairing and restoring used products to make them suitable for use again. Additionally, reverse logistics plays a key role in the recycling and reuse process, where products are collected after use to be sustainably reintegrated into the supply chain.

Voordelen:

Reduction in waste and raw material consumption.

Cost savings through more efficient use of materials.

Positive brand perception due to a focus on sustainability.

4. Real-Time Visibility 2.0

Real-time visibility in supply chains isn’t new, but by 2025, it will reach a new level. Beyond tracking locations, companies will also gather data on the conditions of transported products. Advanced sensors and IoT devices provide insights into factors like temperature, humidity, and shocks. This is vital for industries such as pharmaceuticals and food, where product quality and safety during transport are critical. This new level of transparency helps companies build trust with customers and partners.

Applications in industries:

The applications of sensors play a crucial role in various industries. In the pharmaceutical sector, temperature sensors are used to ensure that medicines remain within the required temperature ranges during transport, which is essential for their effectiveness and safety. In the food industry, humidity and shock indicators help maintain the quality of fresh products, ensuring they reach their destination in optimal condition.

Benefits for businesses:

Greater control and reduced risk of damage or loss.

Increased customer trust through transparency.

Faster decision-making in case of deviations.

5. Localization: The New Norm in Supply Chains

The focus on localization will grow in 2025, not just as a necessity but also as a strategic choice to better serve markets. Companies are investing in local production and distribution networks to operate closer to customers and respond more quickly to specific market demands. This trend is driven by the need for shorter delivery times, customer-centricity, and reduced logistical complexity. Localization also fosters innovation through collaboration with regional partners and a deeper understanding of local needs and regulations.

Why localization?

Customer-centricity:

Operating closer to the market allows companies to better meet changing consumer demand.

Simplified logistics:

Fewer links in the chain mean a simpler process.

Regulatory adaptation:

Local production facilitates compliance and reduces risks related to export restrictions.

Example:

A European electronics manufacturer opens a factory in Poland to meet growing demand in Western Europe more quickly. This shortens delivery times, reduces transport costs, and strengthens relationships with local customers.

6. Human-Centric Logistics: Employees in the Spotlight

While technology is playing an increasingly larger role, human capital remains crucial in logistics. By 2025, the focus will shift to improving working conditions and attracting talent. The shortage of qualified personnel remains a challenge, pushing companies to invest in training, flexibility, and employee well-being. Technology like wearables and augmented reality (AR) will support employees in their daily tasks. Enhancing the work environment will boost productivity and employee satisfaction.

How?

Training and development:

Companies invest in upskilling, such as training on advanced software and equipment.

Supportive technology:

Wearables and augmented reality (AR) assist employees with complex tasks.

Why is this important?

The shortage of skilled personnel persists. Companies that invest in their people remain competitive and attractive to talent.

7. Sustainability as a standard

Sustainability is no longer optional but essential in logistics. Regulations, consumer expectations, and the need to reduce ecological footprints compel companies to adopt green solutions. By 2025, electric trucks, renewable energy sources, and smart packaging will become integral to supply chains. Companies will also focus on carbon offset programs and energy-efficient warehouses. Integrating sustainability into their strategies will strengthen businesses’ competitive positions and relationships with conscious consumers.

Key initiatives:

Transition to electric trucks and sustainable fuels.

Energy-efficient warehouses with solar panels and advanced insulation.

Smart packaging to reduce waste.

Opportunities for businesses:

Sustainability offers both environmental and commercial benefits. Customers increasingly choose brands that take responsibility.

8. Big Data as a Competitive Weapon

Big data is transforming how logistics companies operate. By 2025, its use will expand further, particularly for decision-making and process optimization. Companies can analyze vast amounts of data to forecast demand, manage risks, and minimize delays. Predictive analytics and AI enable more efficient route planning and inventory management. Organizations investing in data infrastructure and analysis will gain a competitive edge in an increasingly complex market.

Applications:

Demand forecasting:

Big data helps anticipate demand fluctuations.

Risk management:

Historical data analysis allows companies to proactively address disruptions.

Efficiency:

Processes are optimized through data-driven insights.

9. Supply Chain Resilience: Flexibility First

Recent years have shown how vulnerable supply chains can be to unexpected disruptions, such as pandemics and geopolitical tensions. By 2025, resilience will become a top priority. Companies will implement strategies like multi-sourcing and scenario planning to prepare for disruptions. Digital twins—virtual models of supply chains—will be used to simulate potential risks and test strategies. A flexible supply chain is not just a defensive measure but also a way to seize opportunities in an unpredictable market.

How companies achieve this:

Multi-sourcing:

Avoiding reliance on a single supplier.

Scenario planning:

Preparing for various potential disruptions.

Digital twins:

Virtual supply chain models help test strategies.

10. Collaboration in the Supply Chain via Blockchain

Blockchain technology is changing the dynamics of supply chains by enhancing transparency and trust. By 2025, blockchain will be widely used to securely and efficiently share information among supply chain partners. Every step of the process—from sourcing raw materials to delivering finished products—can be traced. This is particularly valuable in sectors like food, pharmaceuticals, and high-tech, where regulatory compliance and quality control are essential. Blockchain not only prevents fraud but also improves collaboration and efficiency.

Benefits:

Traceability:

Every process, from raw materials to the finished product, is trackable.

Fraud prevention:

Blockchain prevents data manipulation.

Efficiency:

Shared information enhances collaboration between partners.

Conclusion: Preparing for a Logistics Transformation in 2025

The logistics sector is evolving faster than ever. The trends of 2025 show that technology, sustainability, and flexibility are no longer optional but essential for companies striving to remain competitive. Hyperautomation, self-learning systems, and circular logistics models are setting the tone, while a focus on people-centered work and real-time visibility helps businesses meet the high expectations of customers and partners.

The Future of AI in logistics processes

Although Adaption does not currently use artificial intelligence (AI) in its solutions, we recognize its tremendous potential. AI can play a key role in streamlining logistics processes, such as optimizing routes, forecasting demand, and automating complex tasks. It also offers opportunities to accurately calculate emissions per transport movement, a critical step for companies aiming to reduce their environmental footprint.

At Adaption, we are committed to integrating these technologies in the future. We are actively exploring how AI can enhance our solutions, such as WMS and TMS, enabling companies to operate more efficiently and sustainably.

Sustainability and transparency as core values

Sustainability is no longer a choice but a necessity. Whether it’s implementing circular logistics models, transitioning to electric vehicles, or providing insights into CO₂ emissions per transport movement, companies must take responsibility for their environmental impact. Transparency is key in this regard. With IoT and advanced data tools, businesses can optimize their processes while meeting the growing demand for visibility and reliability.

At Adaption, we focus on developing solutions that help companies measure, report, and reduce their environmental impact. This forms the foundation for sustainable growth and stronger customer relationships.

Bij Adaption richten we ons op het ontwikkelen van oplossingen die bedrijven helpen bij het meten, rapporteren en reduceren van hun ecologische impact. Dit vormt de basis voor duurzame groei en sterkere klantrelaties.

A strategic partner for the future

The trends of 2025 make it clear that the future revolves around collaboration, innovation, and flexibility. We are dedicated to leveraging technological advancements to prepare businesses for the challenges of tomorrow. Our expertise in WMS, TMS, and FMS, combined with our focus on sustainability and transparency, makes us the ideal partner for companies looking to grow in a rapidly changing world.

Do you want to future-proof your supply chain?

Contact us today. Together, we’ll build logistics solutions ready for 2025—and beyond.