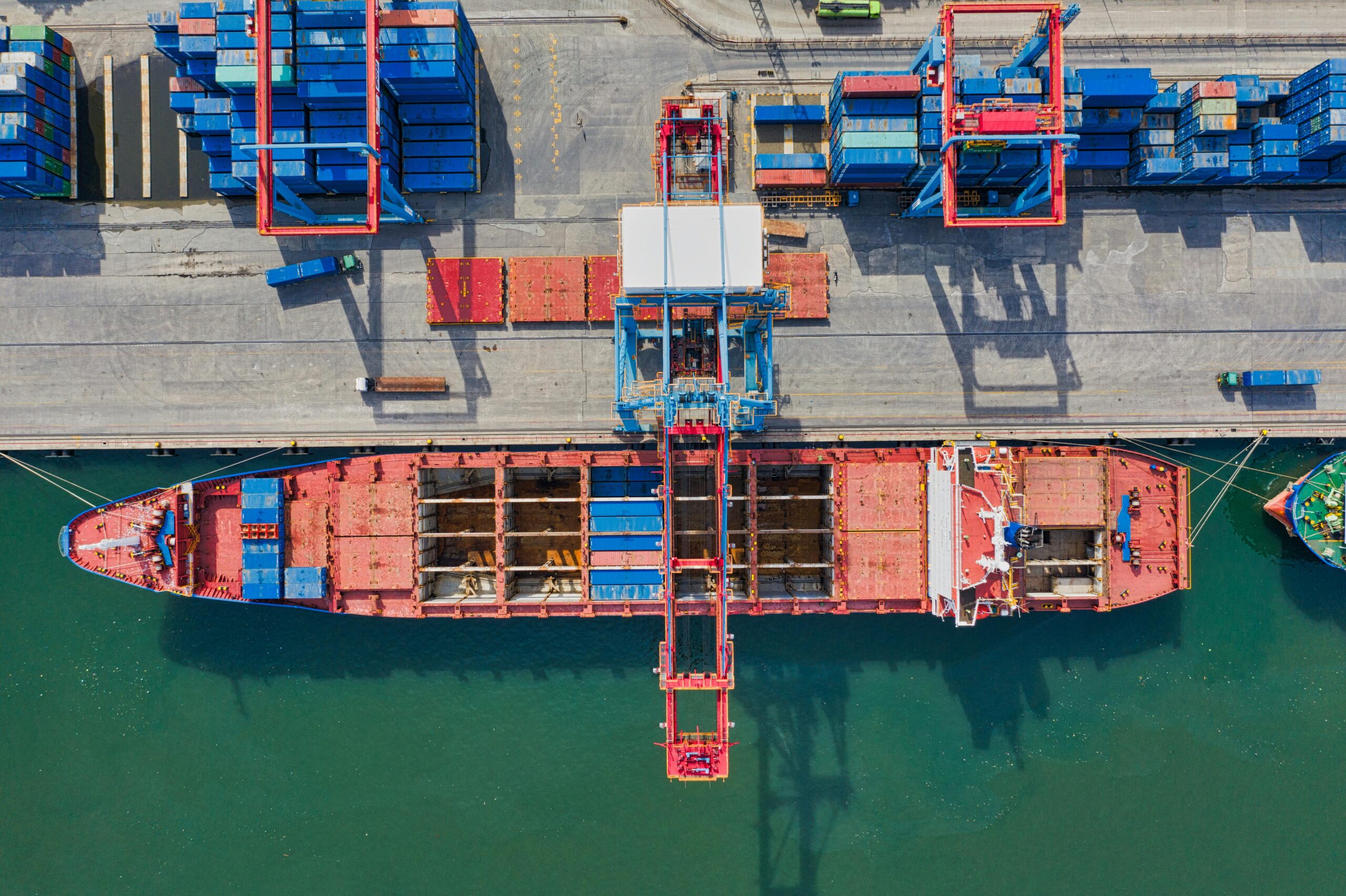

Dockplanning: avoid waiting times and increase the efficiency of your logistics

The right coordination between incoming and outgoing goods flows and internal warehouse processes largely determines how efficiently your logistics operation runs. Waiting times at the dock are not only frustrating but also cost time, money, and capacity. With the advanced dock planning and slot reservation functionalities in Adaption’s Logistics Cloud Suite, you maintain control over your logistics processes, from arrival to departure.

Dockplanning

Smart dock planning with Adaption's TMS

The dock planning tool in Adaption’s Transport Management System (TMS) functions as a clear, visual agenda. Thanks to a straightforward layout with colors and blocks, you can see at a glance which docks are occupied and when. You can configure the docks based on vehicle type, product group, or other relevant variables, so only suitable carriers can book specific docks.

In addition, you can easily enter availabilities, propose and communicate dock allocations, and automatically assign or adjust slot times. All to promote flow and minimize manual coordination.

Smart functionalities for even more control

Separate access rights for planners and carriers

Adaption’s TMS makes a clear distinction between different user roles, ensuring structure and control within your dock planning. Planners have full access to the planning board and can manage all docks, time slots, and reservations. Carriers, on the other hand, have a limited portal with specific rights. For example, they can only book slots within a pre-set time frame, such as a maximum of one hour in advance. This prevents unwanted last-minute changes and makes the planning process clearer and more predictable.

Automatic pre-load times per vehicle type

Efficient planning starts with realistic time schedules. That’s why the system allows you to set a standard loading or unloading time per vehicle type – the so-called pre-load times. Does a certain trailer typically need one hour at the dock? Then this time is automatically entered once the vehicle is booked. This prevents overly tight schedules, ensures optimal dock utilization, and makes the entire loading and unloading process run more smoothly. This automatic time allocation also helps reduce error margins during busy periods.

Smart notifications and communication for changes

In a dynamic logistics environment, changes are a daily occurrence. Adaption’s TMS ensures all parties involved are immediately informed of planning adjustments. When a change occurs, the user automatically receives a notification via email or a pop-up in the system. In addition, reservation confirmations and updates are automatically communicated to carriers. This automation reduces the risk of misunderstandings, increases the reliability of your processes, and saves time that would otherwise be spent on phone calls or email correspondence.

Carrier portal for transparency and self-management

The integrated carrier portal gives logistics partners access to their own view of the dock planning. Here they can reserve slot times themselves, propose changes after allocation, and receive confirmations. This portal increases transparency and gives carriers more autonomy, while you as the shipper maintain full control. Thanks to this feature, processes are accelerated and cooperation between planner and carrier becomes more efficient and professional. Less manual contact also means more time for valuable logistics activities.

The advantages of dock planning at a glance:

Full insight into loading and unloading activities

Shorter waiting times and faster throughput

Lower costs through better planning

Real-time insights for both users and carriers

KPI tracking based on accurate planning data

Direct integration with mobile shop floor applications

Automation of repetitive processes such as dock allocation and communication

Notifications and deviation registration for full control

Use cases: How smart dock planning makes the difference in logistics

Use case 1

More efficient dock occupancy thanks to automatic pre-load times

Jan is a logistics manager at a distribution center where a large number of trucks arrive and depart daily. Planning had long been difficult, mainly because the required loading time per vehicle type wasn’t taken into account. Large trailers were given as much time as smaller vehicles, which often led to delays, congestion, and waiting times at the dock.

After implementing Adaption’s TMS, Jan decided to use the automatic pre-load time functionality. In the system, he set the standard loading time for each trailer type. Since then, the appropriate duration is automatically assigned when booking a slot, tailored to the vehicle. This resulted in a much more realistic planning process, with docks being used more efficiently and waiting times significantly reduced. The shop floor has since become calmer, and the throughput time of the loading and unloading process has greatly improved.

Use case 2

Less communication and more overview with the carrier portal

Sophie works as a planner at a logistics company that collaborates daily with a wide network of carriers. Previously, booking time slots was largely done manually, leading to a constant stream of phone calls and emails. Planning, confirming, and changing slots took a lot of time and often caused confusion or double bookings.

That changed with the implementation of the carrier portal within Adaption’s TMS. Carriers can now reserve their own slots based on current dock availability. They automatically receive confirmations and notifications of changes and can propose alternative times themselves. As a result, the number of manual actions for Sophie has greatly decreased and the planning process has become clearer and more efficient. Cooperation with carriers runs more smoothly, and both Sophie and her colleagues experience more control over the daily planning process.

Conclusion

Optimize your logistics processes with smart dock planning

With Adaption’s TMS, you gain a smart and versatile solution that allows you to fully automate and optimize your dock planning. The system provides you with the tools to efficiently coordinate every aspect of the loading and unloading process, from slot reservations to real-time insight into dock occupancy. This way, you minimize waiting times, lower operational costs, and increase warehouse throughput. You also ensure smoother cooperation with carriers, contributing to more satisfied partners and a more stable supply chain.

Want to know more about how dockplanning can improve your logistics?

Contact us for a no-obligation consultation or schedule a free demo. Together, we’ll achieve your logistics goals and support your company’s growth!